Castleton University

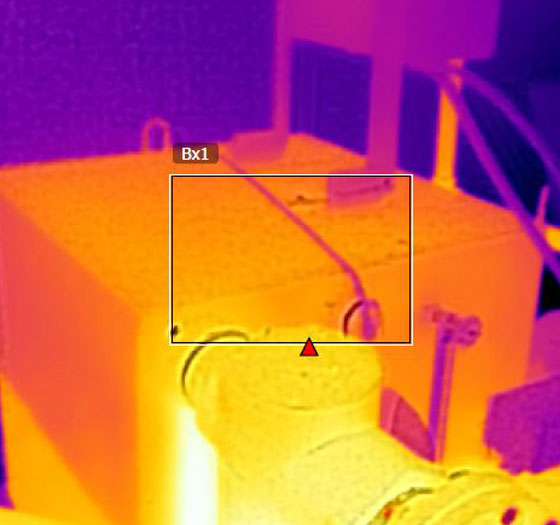

Castleton University is a public university located in Western Vermont with an enrollment of around 2,000 students. Originally dating back to 1787, the 165 acre campus has 21 buildings and was in need of mechanical insulation upgrades to increase their overall efficiency.